Zvese Zvaunoda Kuziva Nezve Injection Molding

Chii chinonzi Jekiseni Molding?

Injection Molding inzira yekugadzira yekugadzira zvikamu muhukuru hukuru. Iyo inonyanya kushandiswa muhuwandu-yekugadzira maitiro apo chikamu chimwe chete chiri kugadzirwa zviuru kana kunyange mamirioni enguva mukutevedzana.

Ndeapi ma polymers anoshandiswa mujekiseni Moulding?

Tafura iri pazasi inoronga zvimwe zvezvinowanzoshandiswa zvinhu:

Acrylonitrile-Butadiene-Styrene ABS.

Nylon PA.

Polycarbonate PC.

Polypropylene PP.

Polystyrene GPPS.

Chii chinonzi jekiseni molding?

Iyo majekiseni epurasitiki ekuumba maitiro anoburitsa huwandu hukuru hwezvikamu zvemhando yepamusoro nekurongeka kukuru, nekukurumidza. Plastiki zvinhu zviri muchimiro chegranules zvinonyungudutswa kusvika zvinyoro zvekuti zvinobayiwa pasi pekumanikidzwa kuzadza mold. Mhedzisiro ndeyokuti chimiro chakanyatsokopwa.

Chii chinonzi jekiseni molding muchina?

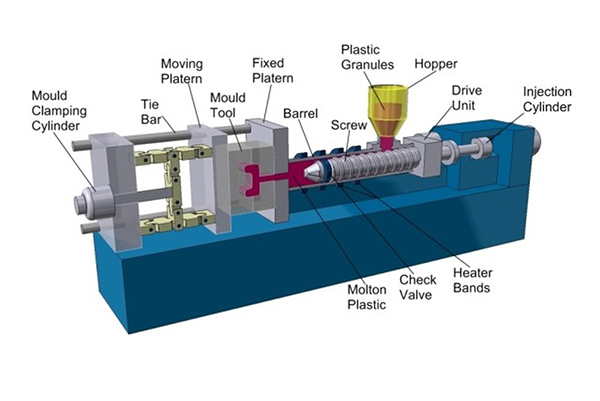

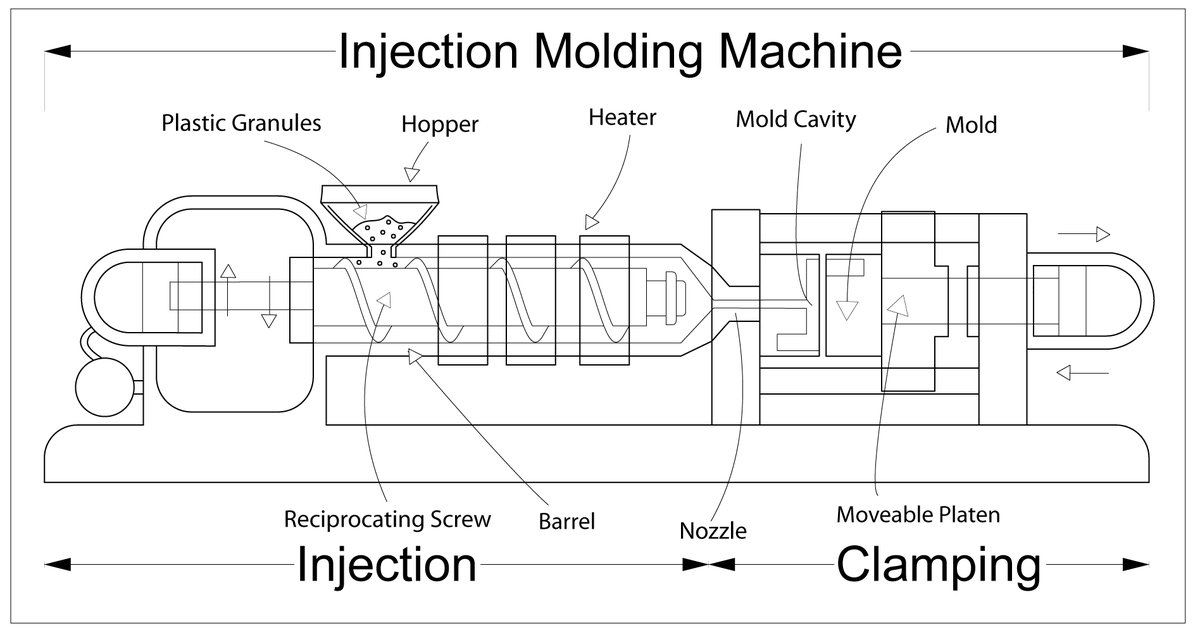

Muchina wekuumba jekiseni, kana (Injection molding muchina BrE), unozivikanwawo semuchina wejekiseni, muchina wekugadzira zvigadzirwa zvepurasitiki nejekiseni rekuumba maitiro. Iyo ine zvikamu zvikuru zviviri, jekiseni unit uye clamping unit.

Michina yekuumba jekiseni inoshanda sei?

Material granules echikamu chacho anodyiswa kuburikidza nehopper mudhiramu rinopisa, rakanyungudutswa uchishandisa mabhendi ekudziya uye kuita kwekukakavadzana kwechinodzoreredza screw barrel. Plastiki rinobva rabaya jekiseni nemumuromo mugomba umo rinotonhodza nekuomesa kusvika pakugadziriswa kwegomba.

Ndeapi Mamwe Mafungidziro Ekuita Injection Molding?

Usati waedza kugadzira chikamu kuburikidza nejekiseni molding funga zvishoma zvezvinotevera zvinhu:

1, Kufunga Kwemari

Mutengo Wekupinda: Kugadzirira chigadzirwa chekugadzira majekiseni akaumbwa kunoda mari yekutanga mari. Ita shuwa kuti unonzwisisa iyi yakakosha pfungwa pamberi.

2, Kugadzirwa Kwehuwandu

Sarudza huwandu hwezvikamu zvinogadzirwa apo jekiseni molding inova inodhura zvakanyanya nzira yekugadzira

Sarudza huwandu hwezvikamu zvinogadzirwa zvaunotarisira kutyora kunyange pakudyara kwako (funga nezvemitengo yekugadzira, kuyedza, kugadzira, kuungana, kushambadzira, uye kugovera pamwe neinotarirwa mutengo wekutengesa). Vaka munzvimbo inochengetedza.

3, Kufunga Kwekugadzira

Chikamu Dhizaini: Iwe unoda kugadzira chikamu kubva pazuva rekutanga uine jekiseni kuumba mupfungwa. Kurerutsa geometry uye kuderedza nhamba yezvikamu kutanga zvichabhadhara migove munzira.

Tool Dhizaini: Ita shuwa yekugadzira iyo mold chishandiso kudzivirira kuremara panguva yekugadzira. Kuti uwane runyoro rwegumi akajairwa jekiseni molding defects uye maitiro ekugadzirisa kana kudzivirira iwo verenga pano. Funga nezvenzvimbo dzegedhi uye mhanyisa simulation uchishandisa moldflow software seSolidworks Plastics.

4, Kufunga nezvekugadzira

Nguva Yekutenderera: Deredza nguva yekutenderera zvakanyanya sezvazvinogona. Kushandisa michina ine hot runner tekinoroji kuchabatsira sezvichave zvakafungwa-out tooling. Shanduko diki dzinogona kuita mutsauko mukuru uye kucheka masekonzi mashoma kubva panguva yako yekutenderera kunogona kuturikira mukuchengetedza kukuru paunenge uchigadzira mamirioni ezvikamu.

Gungano: Gadzira chikamu chako kuderedza gungano. Zvakawanda zvechikonzero kuumbwa kwejekiseni kunoitwa kumaodzanyemba kwakadziva kumabvazuva kweAsia mutengo wekuunganidza zvikamu zvakapfava panguva yekuumba jekiseni.

Nguva yekutumira: Nov-05-2020